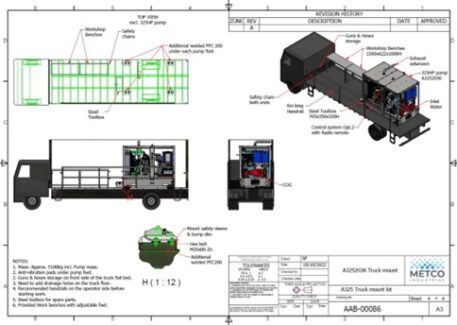

POWER PUMPING - TRUCK MOUNT METCO A325 SKID

Custom Project Description

Our client Power Pumping is an Australian leading Vaccum Excavation and Liquid Waste company. As a regular Metco pump user. Power Pumping requires a UHP pump that will operate in the harshest of conditions. As well as being mobile to get to the areas they need to service. So this project was simple engineer a solution to securely and safely mount a Metco A325 skid pump to their truck.

Project Start Date12.10.2022

Project End Date28.10.2022

CategoryEngineered Mobility

CUSTOM ENGINEERING PROCESS

We start all our custom projects in the same way. We look at what the customer needs to do, then work backward from there. In this case, Power Pumping needed a UHP with enough horsepower to tackle their customer’s UHP projects. They settled on a Metco A325 skid-mount pump – 325 HP, with a 15K, 20K, and 40K PSI Jetstream UHP Pump capability.

With our in-house engineering team. We then custom-designed a solution to safely mount the Metco A325 Skid mount pump to the back of their truck. We maximized the space they had by creating a workspace area that included work benches and a toolbox. The workbenches were custom-designed out of Stainless steel.

Work Scope

Our Engineering team breaks every project down into actionable steps. With consultation with the customer before starting the project, to ensure a positive outcome.

- Engineer solution to securely mount Metco A325 skid pump to the customer-provided truck.

- Modify truck bed frame to accommodate weld-in mounts

- Use a soft mount system to reduce vibrations from the pump through to the truck chassis.

- Determine the best pump position on the truck bed in regard to weight distribution. Truck scales are used to check axle weights.

- Create a workspace area on the truck bed to include workbenches and toolbox.

- Install safety handrails to be compliant with site requirements.